Burullus Power Plant 4800 MW Project

Project Data & EL-Mahd Responsibility

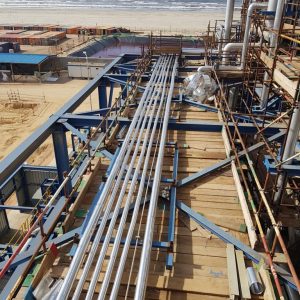

Burullus Combined Cycle Power Plant is one of the world’s largest gas-fired combined cycle power plants with a capacity of 4,800 MW, The mega project consisted of design, engineering, fabrication, delivery of materials and equipment, erection, testing, commissioning, startup, and putting into service the Burullus Combined Cycle Power Plants at ISO Condition, Burullus Combined Cycle Power Plant was completed in a record time, The execution schedule was extremely challenging at Burullus Power Plant. In addition, the plant’s remote site required additional complex geotechnical engineering with significantly greater soil improvement and piling work than expected.

El-Mahd Company obtained a contract for the implementation of mechanical works related to Module 1, 2, including installation of mechanical equipment, fabrication and installation of a network of carbon steel, stainless steel and alloy pipes (P91-P22-P11) and thermal insulation works, including all related activities such as (unloading materials manufacturing, heat treatment, testing, pre-commissioning and commissioning).

El-Mahd Company has employed qualified direct manpower as technicians and supervisory staff at the highest level of experience, efficiency and indirect manpower from an integrated engineering office that includes the Technical Office Department, Quality Department, and H.S.E Department, as well as supplying all raw materials consumed in all work steps, in addition to providing All heavy and light equipment and hand tools, as well as providing administrative offices, warehouses and a fully equipped manufacturing workshop at the work site.

The Scope Of Work

The scope of work was mainly the piping network and mechanical systems, where El-Mahd Company carries out all related activities, starting from receiving raw materials from the customer’s warehouses and storing them in the fabricating area, then manufacturing in the workshop equipped with all manufacturing equipment and then installing all piping networks in the project with all its mechanical attachments of pumps and supports…etc.

Concluding with the work of all the destructive and non-destructive tests required by the project and the radiological imaging with the highest level of safety and quality, in order to reach commissioning phase.

El-Mahd achieved the project completion target supported with a professional documentation record and reporting by the planned project schedule.

Project Gallery